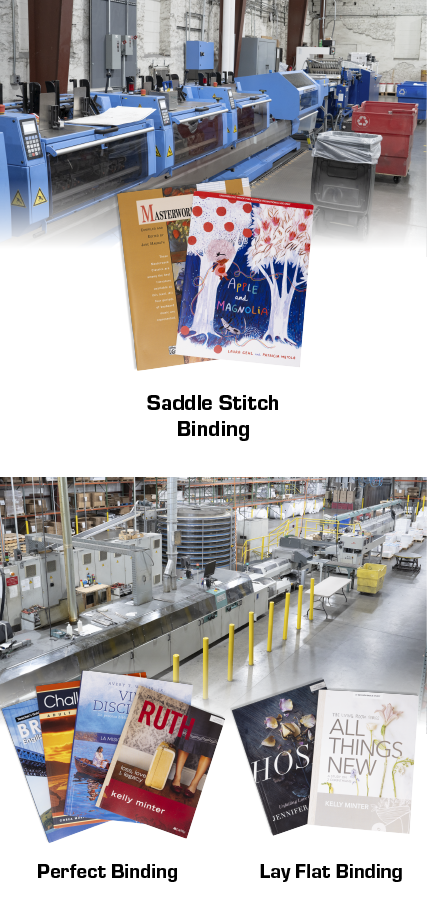

Printing Services

Vicks produces soft cover books serving niche publishers in the Childrens, Educational, Literacy, Music, and Religious markets. Our team works closely with clients to determine the most efficient workflows that make it easy to submit files. We take great pride in the quality of our work and work closely with partners to meet delivery requirements both domestically and internationally.

The best production method is chosen to match product specifications and run lengths. Shortest quantities are run on digital cut sheet devices. Ink jet production takes over for medium and larger runs. Our extensive bindery supports digital and offset processes. We tap long standing partners to produce components or titles, to complement our core capabilities.

Trim sizes:

- 6 x 9″

- 7 x 10″

- 8.5 x 11″

- 9 x 12″

Vicks installed its digital book factory in 2003 responding to our customers desire to keep slower selling titles in print. The key for efficient production of small quantities is the electronic workflow that eliminates “touches.” Our portals ingest multiple titles at once. Reprints go directly to our print engines ready to run. Electronic notification is sent upon the products completion, and if sent to one of our warehouses, upon receiving the product.

The latest cut sheet devices manufacture the shortest quantity jobs. The Hewlett Packard (HP) HDT240 ink jet takes over for longer runs. The HP ink jet’s precision and efficiency is the best in the industry.

Inkjet saddle product is rewound and sent to our new Mueller Martini Presto II binder that provides great efficiencies and flexibility. Bookblocks are created in line with the ink jet then sent to our PUR lay flat binding line.

Inkjet saddle product is rewound and sent to our new Mueller Martini Presto II binder that provides great efficiencies and flexibility. Bookblocks are created in line with the ink jet then sent to our PUR lay flat binding line.

Sell your products in Europe? We send your files to our UK partner, Caligraving Ltd., located just north of London. Our production methods, workflow and capabilities are similar resulting in seamless workflows. Caligraving and Vicks have been partners since 2005 allowing customers to print and ship locally getting products to market faster and cost effectively.